KnowledgeECONOMICS

CONTACT US

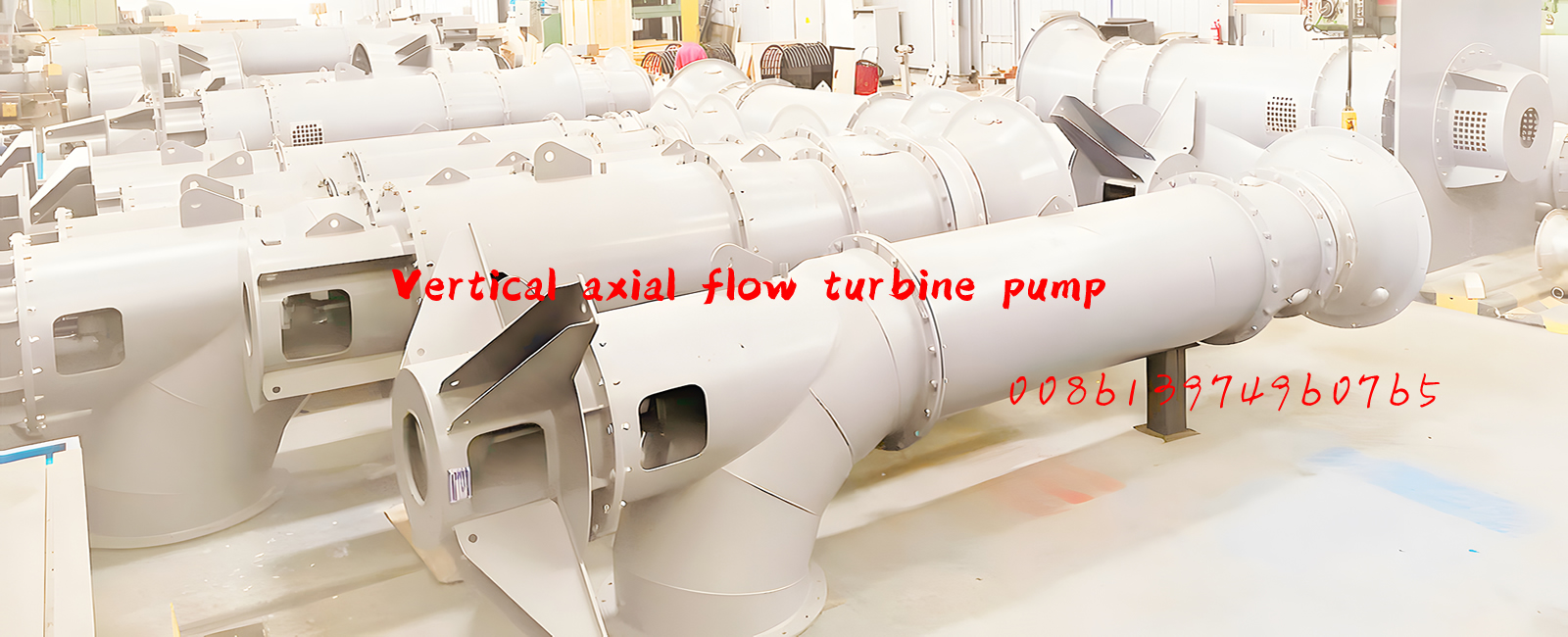

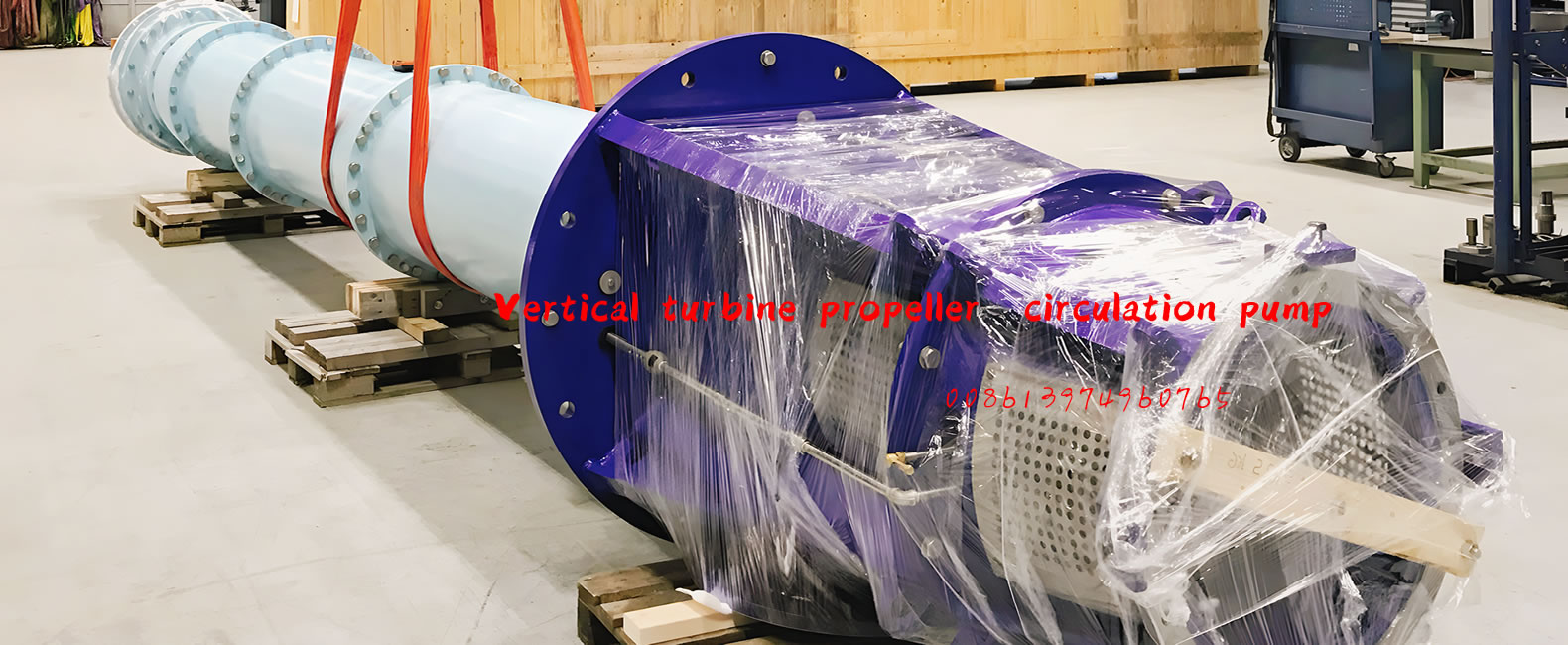

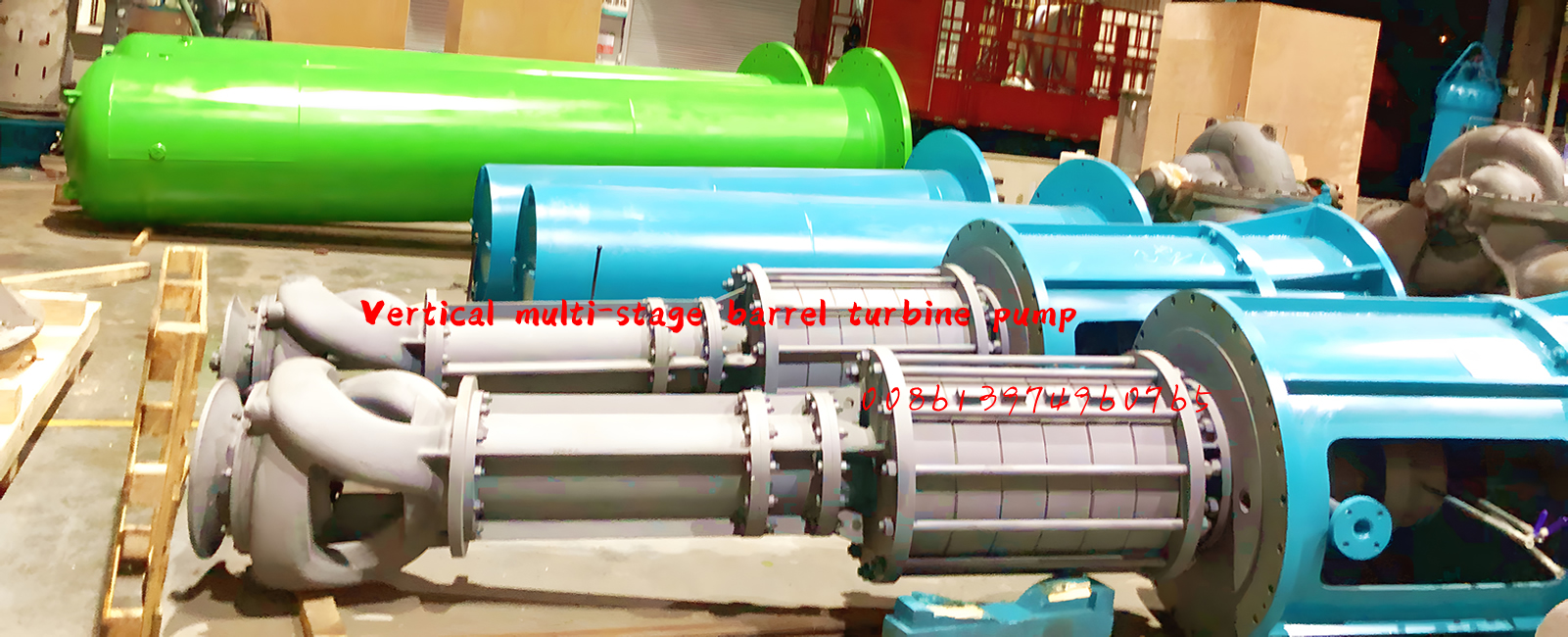

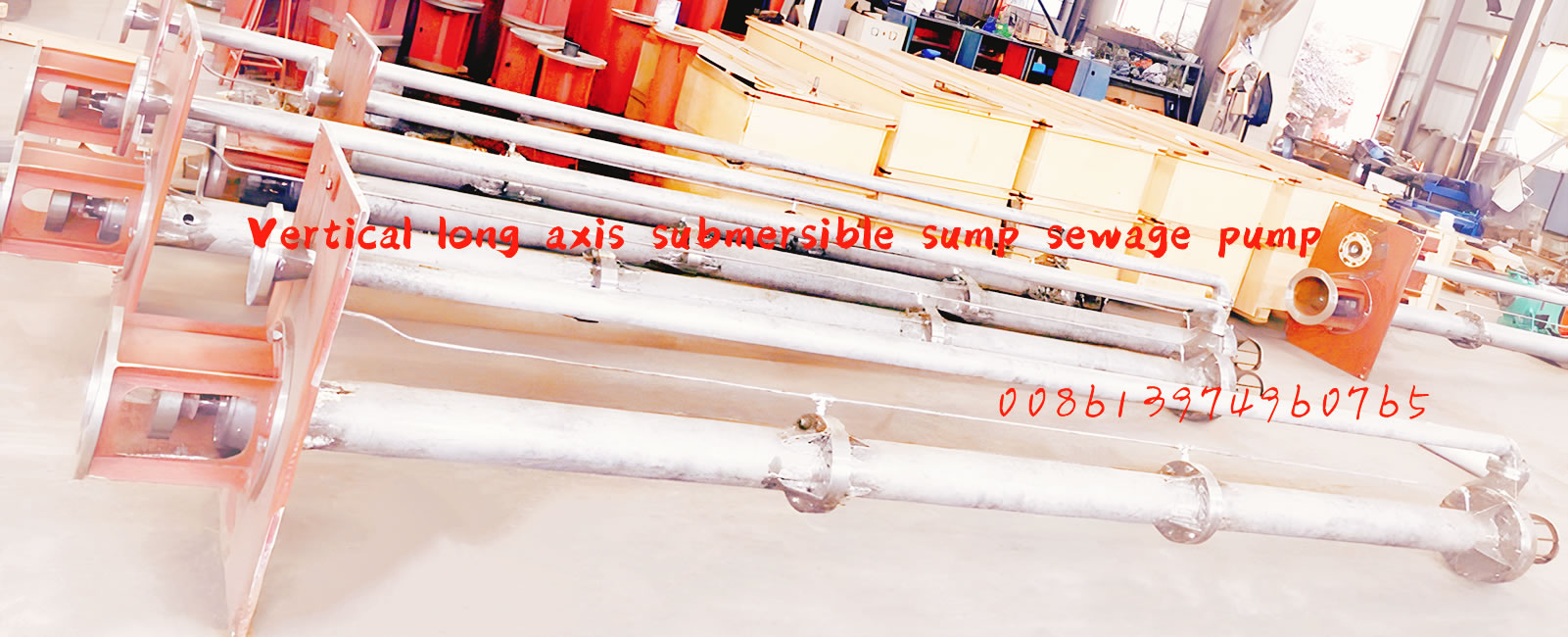

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »vertical turbine pump

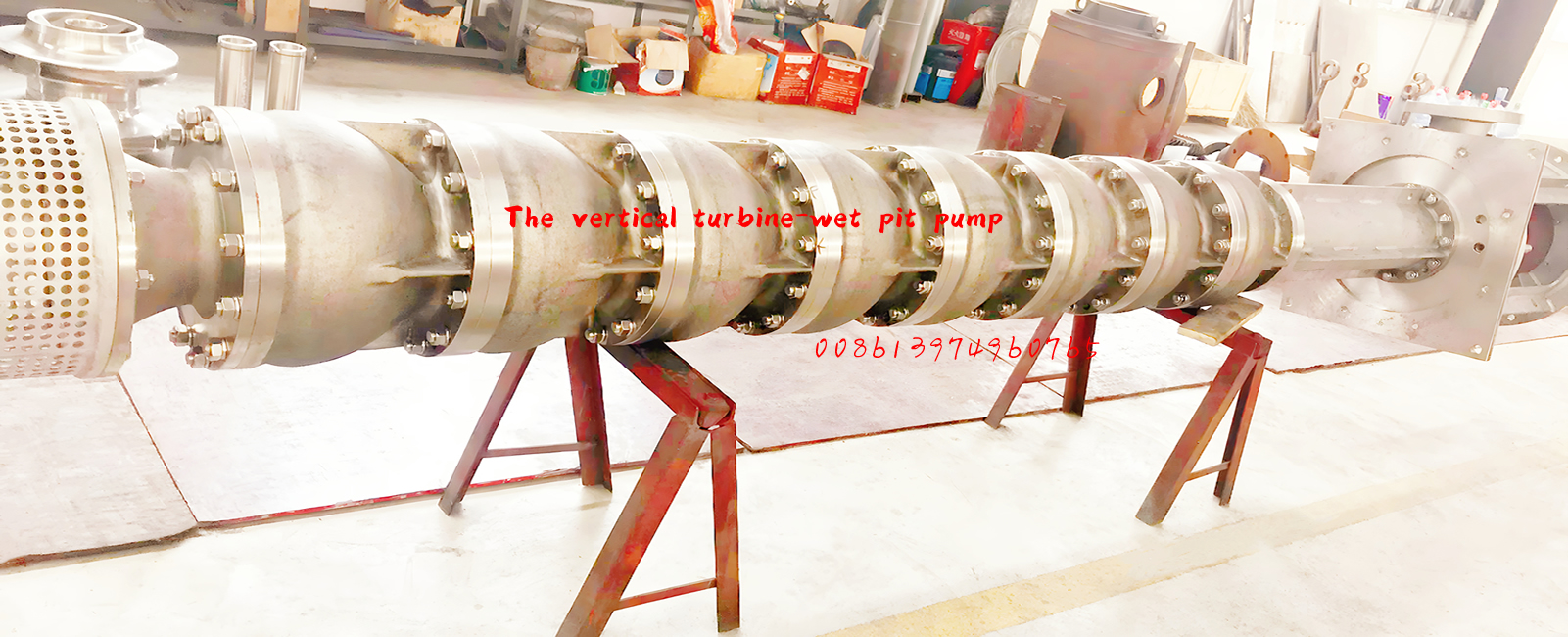

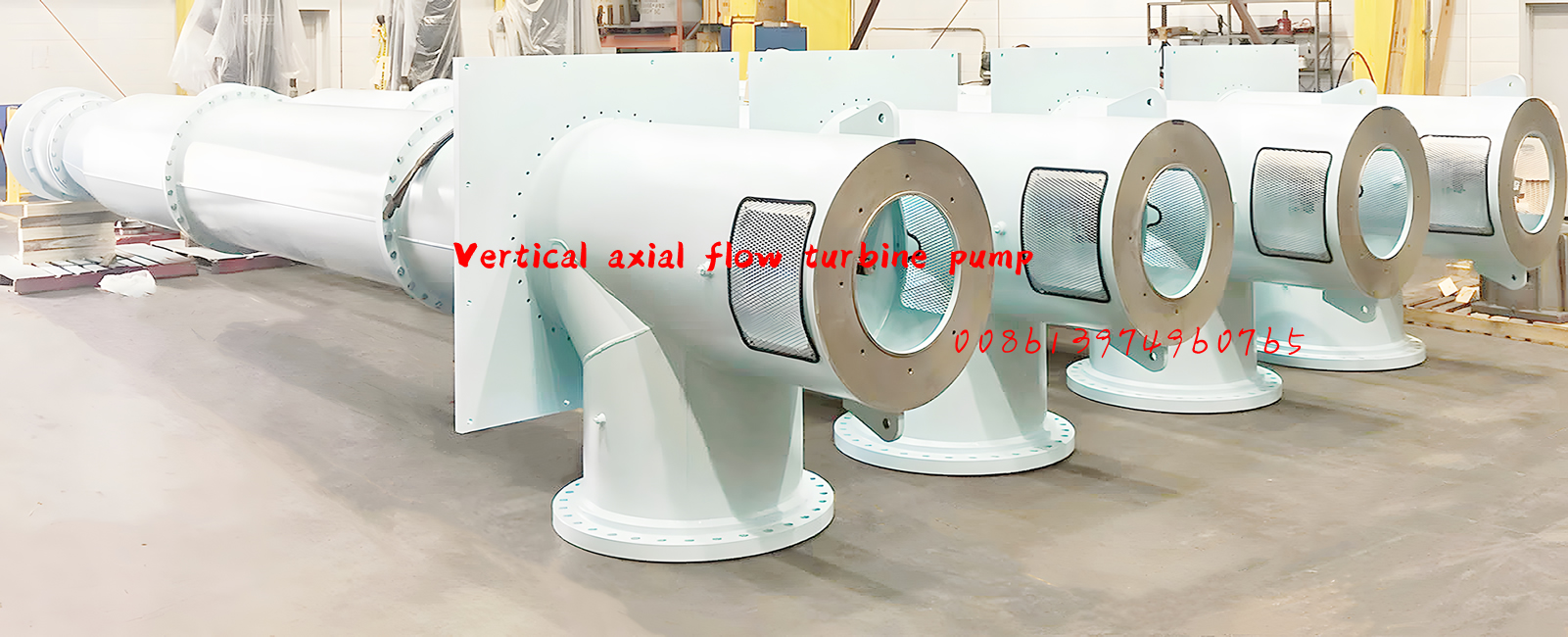

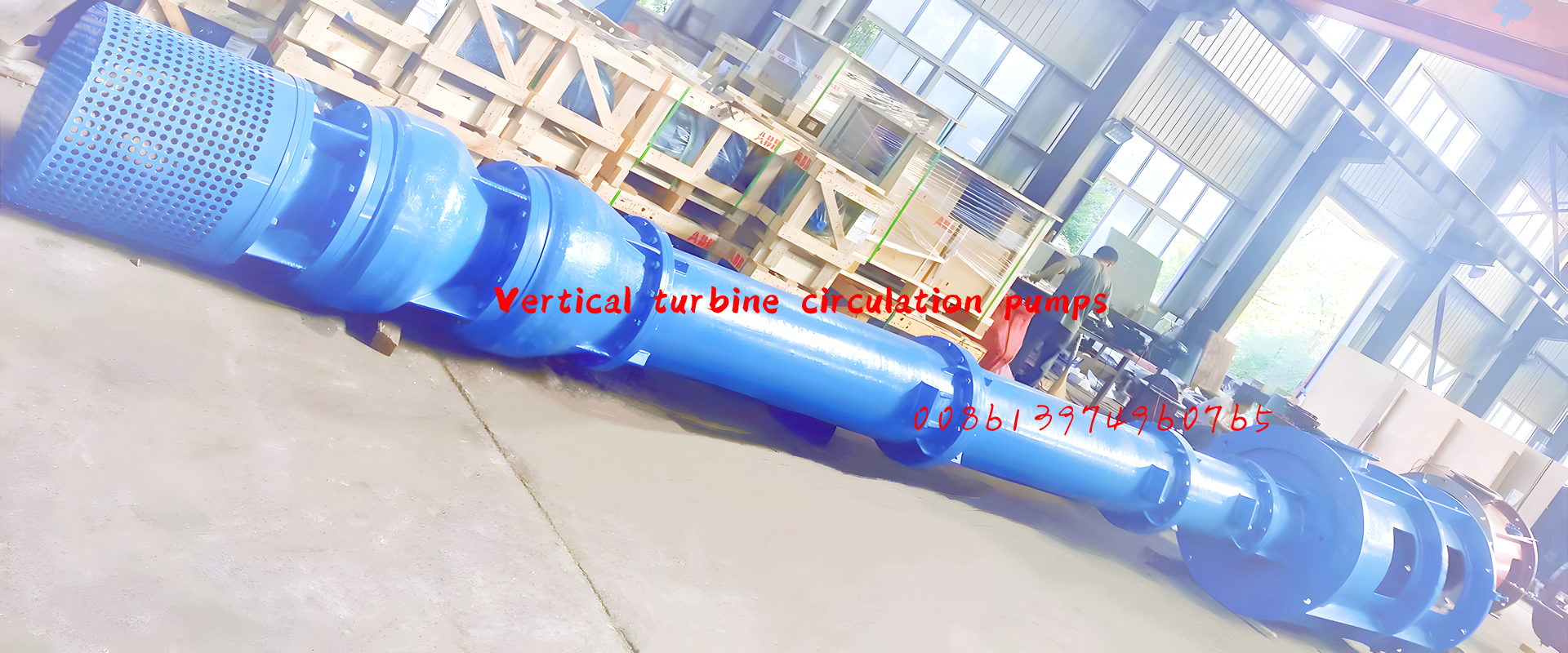

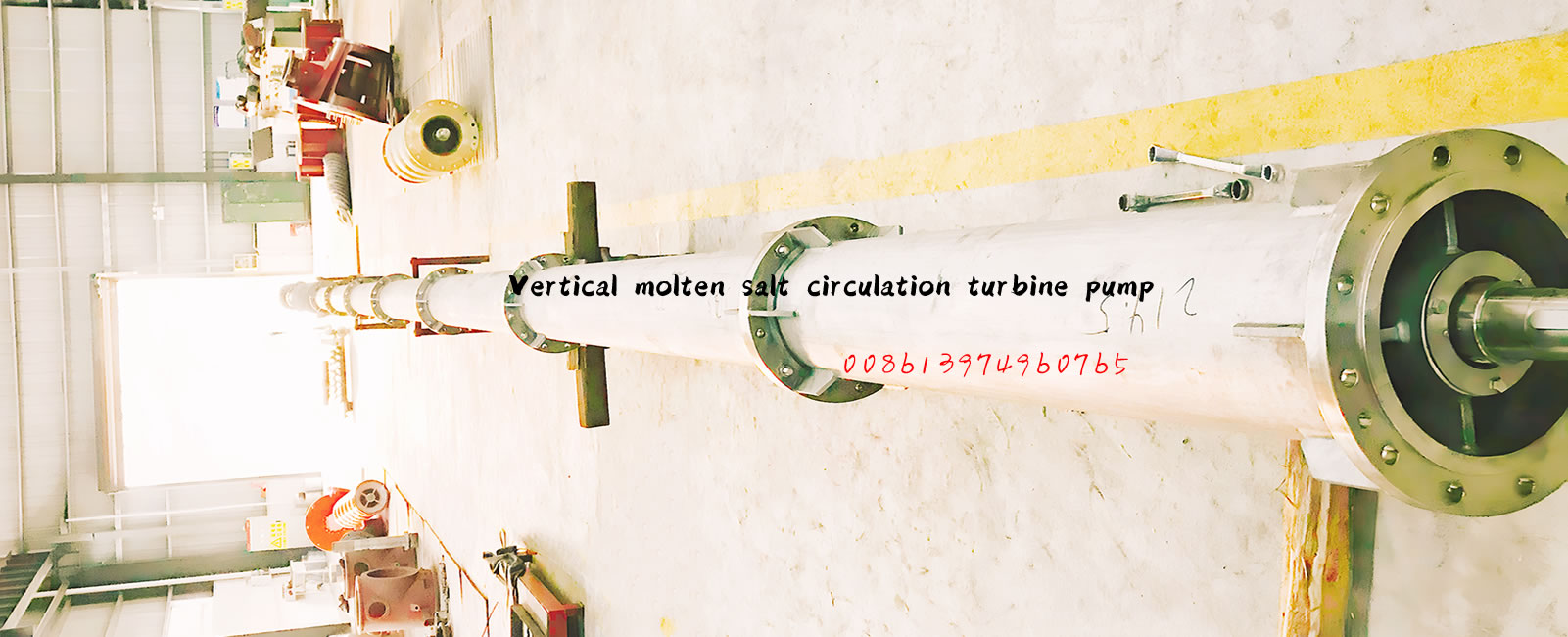

Configuration examples of The Perfect Industrial universal vertical turbine pumps

common construction

1. Adjusting nut located at top of motor-makes impeller adjustment easy.

2. Ratchet prevents backspin-and avoids damage to pump in case of phasereversal (optional).

3. Heawy duty thrust bearing-cooled by air entering motor.

4. Separate motor shaft with coupling in head shaft-facilitates installation;permits changing drives without raising pump.

5.coupling guard-supplied as standard feature.

6. Stainless steel top shaft-may be inverted to renew wearing surface (optional) *not shown on Oil Lubricated.

7. Discharge head-maintains accurate alignment between motor and columnshaft assembly (some discharge heads feature threaded column connections;refer to factory).

8. Recessed base plate-permits casing or sleeve to extend above found.ation as reguired by many health departments (optional) *not shown.

9. High strength line shaft heat treated, ground and polished stainlesssteel: one-third stronger than ordinary shaft.

10.Bowl bearings-bronze on all enclosed impeller pumps: rubber on allsemi-enclosed impeller pumps (other materials available).

11.Enclosed or semi-open impellers- choice of bronze, cast iron or stainless steel(other materials available).

12. Stainless steel impeller shaft-heat treated, ground, and polished forlonger life.

13. Suction bearings-protected with sand collar and packed with non.soluble grease (other materials available).

14.Pre-lubrication connection-through stuffing box distributes water aroundshaft for proper lubrication before start up (optional) *not shown onProduct Lubricated.

Product Lubricated only

15. Stuffing box-with controlled lubrication for extended packing life.

16. Water lubricated shaft bearings-fluted, resillent rubber bearings lubricat-ed by water flowing through the pump; bearings are held in place by amachined bronze bearing retainer secured between two pipe ends (othermaterials available).

17. Coupled column-machined for tight-fitting butt joints (threaded columnavailable, not shown).

Oil Lubricated Only

18. Gun-fil grease cup to lubricate suction bell/case sleeve bearing-factory prefilled.

19.Bronze tube tension nut-easily accessible for placing tube under propertension, also provides close-fitting bearing in pump head.

20. Tube tension nut adapter plate with o-ring-assures watertight seal aroundshaft and enclosing tube.

21. Heavy duty steel shaft enclosure tube-protects line shaft, machined foraccurate bearing alignment.

22. Bronze connector bearings-maintain accurate alignment for line shaft anda coupling for enclosure tube (spiraling internal oil groove lubricatesuniformly and passes oil to bearings below).

23. Relief ports in discharge case-prevent water from rising in tube above water level in well.

24. Water diverting slinger- redirects water as it works its way up the shaft out ofthe discharge case or column case ports, back to the tank or well.

NOTE:*Indicates optional and/or not shown feature.